Dilatation seals, also known as expansion joints or expansion seals, are essential components used in construction, engineering, and infrastructure projects to accommodate movement and expansion between adjoining structures, building elements, or components. These seals are designed to absorb thermal expansion, seismic activity, settlement, and other forms of movement, thereby preventing structural damage, cracking, or failure. Dilatation seals come in various forms and materials, each tailored to specific applications and environmental conditions.

Here’s a detailed description of dilatation seals, their types, functions, applications, and installation:

- Types of Dilatation Seals:

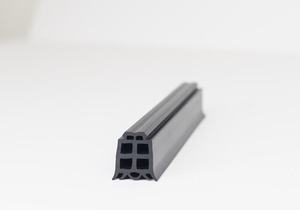

- Movement Joint Seals: These seals are installed in joints between building elements such as floors, walls, and ceilings to accommodate movement caused by thermal expansion, contraction, or settlement. Movement joint seals may consist of materials such as elastomeric compounds, rubber, or metal profiles, depending on the magnitude and direction of movement.

- Bridge Expansion Joints: Bridge expansion joints are specialized dilatation seals used in bridge construction to accommodate movement and deformation caused by temperature changes, traffic loads, and seismic activity. These joints are typically made from materials such as neoprene, rubber, or steel and are installed between adjacent bridge segments or bridge decks.

- Pipeline Expansion Joints: Pipeline expansion joints are employed in piping systems to absorb thermal expansion and contraction, as well as vibrations and mechanical movements. These joints may be composed of materials such as rubber, metal bellows, or fabric-reinforced elastomers, depending on the application and operating conditions.

- Wall and Facade Seals: Wall and facade seals are used to seal joints and gaps in exterior walls, curtain walls, and facade systems to prevent water infiltration, air leakage, and thermal bridging. These seals are often made from silicone, polyurethane, or rubber and are designed to accommodate both horizontal and vertical movement.

- Floor Expansion Joints: Floor expansion joints are installed in floor assemblies to allow for movement caused by temperature changes, moisture fluctuations, and structural settlement. These joints may feature covers or profiles made from materials such as aluminum, stainless steel, or PVC, providing a durable and aesthetically pleasing solution for commercial and industrial flooring applications.

- Functions of Dilatation Seals:

- Movement Accommodation: The primary function of dilatation seals is to accommodate movement and expansion between adjacent structures or building elements, thereby preventing cracking, deformation, or damage.

- Waterproofing and Weatherproofing: Dilatation seals act as barriers against water infiltration, air leakage, and environmental elements such as rain, wind, and snow, ensuring the integrity and durability of building envelopes and infrastructure.

- Noise and Vibration Damping: In addition to accommodating movement, dilatation seals can dampen noise and vibrations transmitted between building components, improving occupant comfort and reducing structural fatigue.

- Aesthetic Enhancement: Dilatation seals are available in a variety of colors, profiles, and finishes to complement architectural designs and enhance the visual appearance of buildings, bridges, and other structures.

- Applications of Dilatation Seals:

- Building Construction: Dilatation seals are extensively used in commercial, residential, and institutional buildings to seal joints in floors, walls, ceilings, and facades, providing waterproofing, weatherproofing, and movement accommodation.

- Infrastructure Projects: In infrastructure projects such as bridges, highways, railways, and tunnels, dilatation seals are employed to accommodate movement and expansion in structural elements, ensuring the longevity and safety of transportation networks.

- Industrial Facilities: Dilatation seals are utilized in industrial facilities such as power plants, refineries, and manufacturing plants to seal joints in pipelines, tanks, and equipment, preventing leaks, vibrations, and structural damage.

- Seismic Retrofitting: In earthquake-prone regions, dilatation seals are incorporated into existing buildings and structures as part of seismic retrofitting measures to enhance resilience and mitigate the effects of seismic activity.

- Installation of Dilatation Seals:

- Surface Preparation: Before installing dilatation seals, ensure that the joint surfaces are clean, dry, and free from any debris, contaminants, or irregularities that could affect seal performance.

- Proper Sizing and Positioning: Select dilatation seals of appropriate size, profile, and material based on the magnitude and direction of movement, as well as the specific requirements of the application. Position the seals accurately within the joint to ensure proper function and compatibility with adjacent components.

- Anchoring and Fixing: Secure dilatation seals to the substrate using appropriate anchoring methods such as adhesives, mechanical fasteners, or integrated mounting systems. Ensure that the seals are securely anchored while allowing for movement in all directions.

- Sealant Application (if necessary): Apply compatible sealants or adhesives to the joint surfaces as required to enhance sealing performance and adhesion. Follow manufacturer recommendations for sealant selection, application, and curing to ensure optimal results.

- Testing and Inspection: After installation, conduct visual inspections and functional tests to verify that the dilatation seals are properly installed, aligned, and functioning as intended. Address any issues or deficiencies promptly to ensure long-term performance and durability.

In summary, dilatation gaskets are critical components in construction, engineering, and infrastructure projects, providing essential functions such as movement accommodation, waterproofing, weatherproofing, and aesthetic enhancement. With their versatility, durability, and performance characteristics, dilatation seals contribute to the longevity, safety, and sustainability of buildings, bridges, pipelines, and other structures in diverse applications and environments.